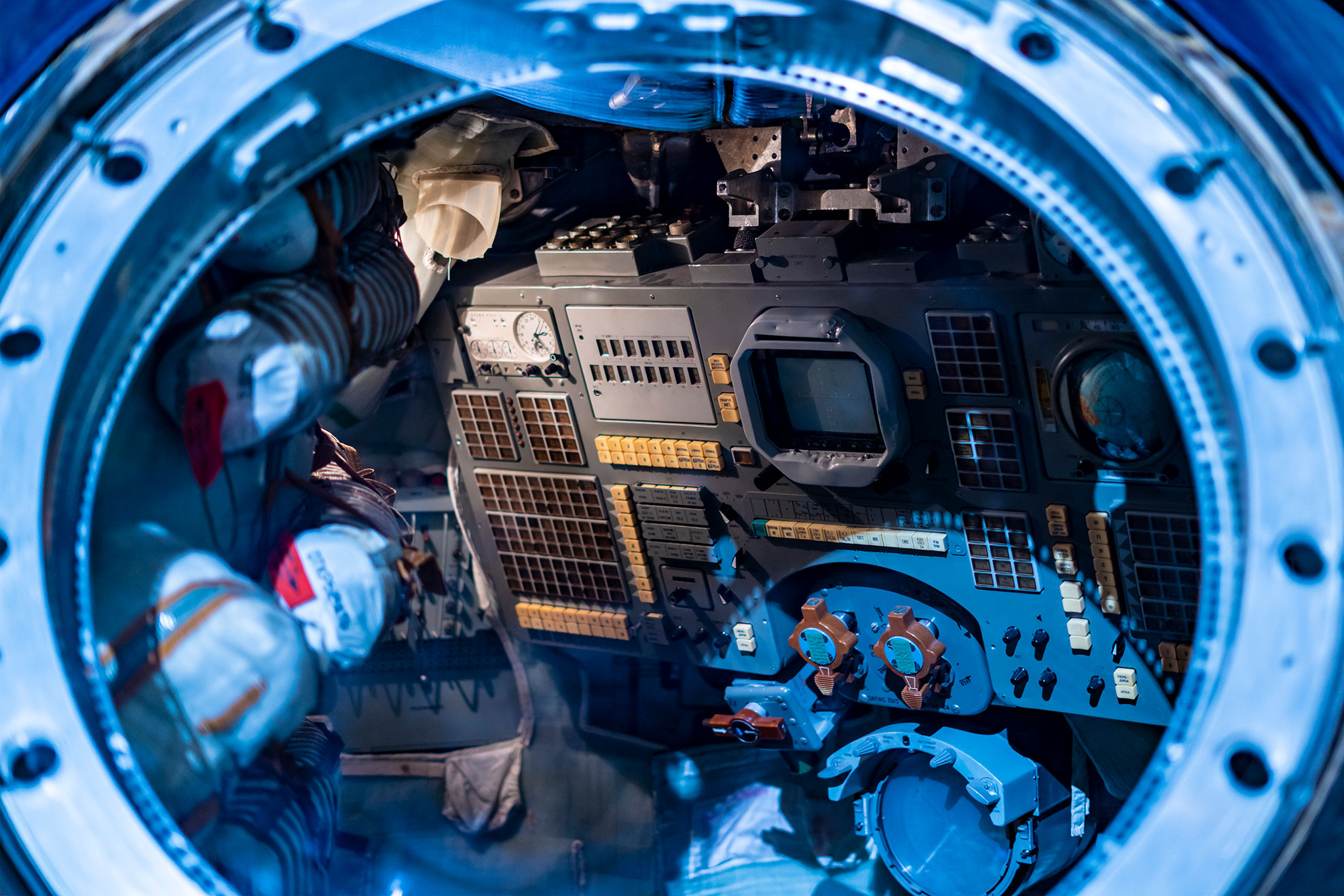

Lean manufacturing, a major lever for optimizing aeronautical MCO

Faced with disparate availability rates for different fleets, which impact on the ability of forces to meet operational requirements, aeronautical support providers have a key role to play: guaranteeing fleet availability in line with requirements, while keeping costs under control.

The deployment of a lean manufacturing allows you to rethink processes (identifying bottlenecks and business irritants) and reorganize workshops to reduce the number of leadtimes and improved working conditions for operators.

Support in place

Our teams have structured an approach around two complementary pillars: support in the field to optimize availability rates, in close collaboration with operators, and support for the professionalization of the entire structure in terms of operating methods. lean management, to help empower her:

- Leading lean DMAIC projects, on industrial maintenance processes as well as administrative processes.

- Leading 5S projects (reorganization of workshops).

- Kaizen breakthrough animation.

- Operator training based on a «training-action» approach.

- Identification, with operators, of sites to be handled independently by their teams.

The results

And tomorrow?

Backed by a large community of staff trained in the methods of the lean management (Green Belt, Black Belt, Master Black Belt...) spread across all its sites, our customer is now in a position to independently lead continuous improvement projects, to improve fleet availability.